What is Sheet Metal Stamping?

Sheet metal stamping involves several metal forming processes, including punching, bending, and drawing, to create parts from sheet metal. This manufacturing method is highly efficient and allows for:

- High Precision: The use of dies ensures that parts are produced with tight tolerances, which is critical for applications in the automotive and aerospace industries.

- Repeatability: Once a die is created, it can produce thousands of identical parts with consistent quality.

- Material Efficiency: Sheet metal stamping minimizes waste, making it a cost-effective solution for manufacturers.

Our state-of-the-art manufacturing facilities are equipped with advanced technology and machinery, enabling us to produce a wide range of sheet metal stampings with exceptional precision and efficiency. Our team of skilled engineers and technicians work diligently to ensure that every component is crafted to the highest standards, guaranteeing durability and performance..

Advantages of Sheet Metal Stamping

- Precision and Complexity: Sheet metal stamping allows for the creation of complex parts and components with high precision.

- Uniform Wall Thickness and High Strength: sheet metal stamping parts have the advantage of uniform wall thickness, small wall thickness, light weight, and high strength.

- Cost-Effectiveness for Small Production Runs: Transfer die stamping, a method within sheet metal stamping, is highly effective and economical for small production runs.

- Minimal Waste and Inexpensive Tooling: Four-slide stamping, a variation of sheet metal stamping, offers the advantage of relatively inexpensive tooling and minimal waste production during the process.

- Quick and Reliable Production: Metal stamping is a quick, reliable, and effective way to produce intricate shapes from sheet metal. The affordability, quality, and manufacturing speed that metal stamping offers are major reasons why many industries choose this process to develop durable parts and products

- Cold Forming Technique: Reduces waste and enhances efficiency by avoiding the need for secondary operations. Chassis Components: Produce frame rails, cross members, and suspension mounts. Interior Components: Fabricate trim components like instrument panels and seat frames.

Applications in the Automotive Industry

Automotive Industry

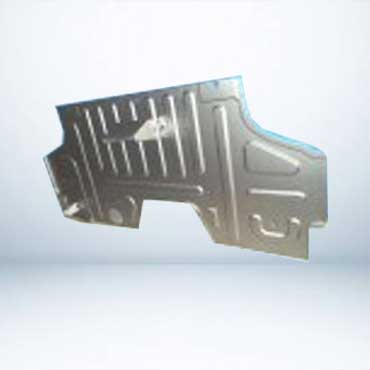

- Body Panels: Sheet metal stamping is extensively used to manufacture automotive body panels such as doors, hoods, fenders, and trunk lids..

- Chassis Components: Stamping manufacturers produce structural components for vehicle chassis, including frame rails, cross members, and suspension mounting brackets.

- Interior Components: Fabricate trim components like instrument panels and seat frames.

Why Choose Devchhaya Group of Industries?

Quality Assurance: We adhere to stringent quality control measures throughout the manufacturing process, ensuring that our sheet metal stampings meet industry standards and customer specifications. Wide Range of Materials: We offer sheet metal stampings in a variety of materials, including stainless steel, aluminum, brass, and more, allowing us to cater to specific project requirements. Custom Solutions: Understanding that every project is unique, we provide customized solutions tailored to meet the individual needs of our clients. Whether it's a specific design or volume requirement, we are here to help. Timely Delivery: Our streamlined production processes and efficient supply chain management enable us to deliver products on time, ensuring that your projects stay on schedule.Manufacturing Process Precision Sheet Metal Stampings

- Material Preparation: The process begins with selecting the appropriate sheet metal, which can include materials like steel, aluminum, copper, and stainless steel. The metal is cut into blanks that will be fed into the stamping press.

- Feeding the Metal: The prepared metal sheets are fed into a stamping press. This machine is equipped with a die that shapes the metal into the desired form. The precision of the die is crucial, as it determines the final dimensions and quality of the stamped part.

- Stamping Operation: The stamping press applies tremendous force to the die, which either cuts, bends, or forms the metal into the required shape. This can involve various techniques such as blanking, piercing, bending, and embossing. The result is a high-precision component that is often more reliable than parts produced through manual machining methods

- Quality Control: At Devchhaya Group of Industries, we prioritize quality assurance throughout the stamping process. Each component undergoes rigorous testing to ensure it meets industry standards and customer specifications. Our commitment to quality is reflected in our ISO certifications and adherence to best practices in manufacturing.

- Finishing Touches: After stamping, components may require additional processes such as coating, painting, or surface treatment to enhance durability and aesthetics. We offer a range of secondary services to ensure that our products are ready for immediate use in various applications

Diverse Services

As Sheet Metal Stampings Manufacturers, Suppliers, Exporters In India we offer a wide range of services to meet the needs of our clients:

- Custom Stamping: We specialize in creating custom metal stampings that meet your specific design and performance requirements. Our team works closely with you to understand your needs and provide tailored solutions.

- Progressive Stamping: This technique allows us to perform multiple operations in a single pass, which is ideal for high-volume production. It improves efficiency and reduces production time.

- Deep Drawing: For components that require forming deep, hollow shapes, our deep drawing capabilities are perfect. This process is commonly used for items like automotive parts and packaging.

- Bending and Forming: Our bending and forming services ensure that we can create complex shapes and angles, enhancing the functionality of the final product.

- Assembly Services: In addition to stamping, we offer assembly services for complete solutions. We can assemble components into finished products, saving you time and resources.

Devchhaya Industries is a leading Sheet Metal Stampings Manufacturers, Suppliers, Exporters company in India, known for its precision, versatility, quality, innovation, and customer-centric approach. With a focus on delivering excellence in every component it manufactures, Devchhaya Industries continues to set the benchmark for sheet metal stamping manufacturing in India.

Tags: Sheet Metal Stamping Services | Custom Sheet Metal Stamping | Sheet Metal Stamping Solutions | Sheet Metal Fabrication Suppliers | Metal Sheet Stamping Manufacturers | Precision Sheet Metal Stamping Manufacturers | Industrial Sheet Metal Stamping Manufacturers | Sheet Metal Stamping Exporters | Sheet Metal Stamping Traders | Sheet Metal Stamping Dealers | Sheet Metal Production Companies | Retailers of Sheet Metal Products | Sheet Metal Stamping Industry