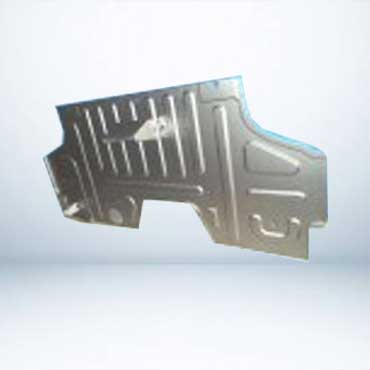

About Sheet Metal Assemblies

Sheet metal assemblies are integral components in various industries, formed by combining multiple sheet metal parts into a single unit. These assemblies can include enclosures, brackets, cabinets, and more, designed to meet specific functional and aesthetic requirements. The versatility of sheet metal allows for a wide range of applications, making it a popular choice in manufacturing.

Features of Sheet Metal Assemblies

- Customizability: Sheet metal assemblies can be tailored to meet specific dimensions and designs, accommodating unique project requirements.

- Durability: Made from robust materials, these assemblies are resistant to wear and tear, making them suitable for both indoor and outdoor applications.

- Lightweight: Despite their strength, sheet metal assemblies are relatively lightweight, which is advantageous for transportation and installation.

- Finishing Options: Various finishing techniques, such as powder coating and anodizing, can enhance the appearance and corrosion resistance of the assemblie

Advantages of Sheet Metal Assemblies

- Cost-Effectiveness: The manufacturing processes for sheet metal assemblies are often more economical compared to other materials, making them a budget-friendly option for many projects.

- Efficiency in Production: The simplicity of working with sheet metal allows for faster production times, which is crucial for meeting tight deadlines.

- Versatility: Sheet metal can be easily formed into various shapes and sizes, making it suitable for a wide range of applications across different industries

- Strength-to-Weight Ratio: Sheet metal assemblies provide excellent strength while remaining lightweight, which is particularly beneficial in applications where weight is a concern

Manufacturing Process of Sheet Metal Assemblies

The manufacturing process of sheet metal assemblies involves several key stages, each critical to producing high-quality components for various applications, particularly in the automotive industry.

Material Selection

Choosing the right material is fundamental in sheet metal fabrication. Common materials include steel, aluminum, and copper, each offering unique properties such as strength, weight, and corrosion resistance. The selection depends on the specific requirements of the final product, including durability and performance under various conditions.

Cutting Techniques

Cutting is the first step in the sheet metal manufacturing process. Various techniques are employed, including:

- Shearing: Used for straight cuts on flat sheets.

- Laser Cutting: Provides high precision for complex shapes.

- Plasma Cutting: Suitable for thicker materials and intricate designs.

These methods ensure that the metal sheets are cut to the desired dimensions before further processing.

Forming and Bending

Once the sheets are cut, they undergo forming and bending processes to achieve the required shapes. Techniques such as press braking and roll forming are commonly used. These processes not only shape the metal but also enhance its strength and stiffness, making it suitable for structural applications.

Welding and Joining

After forming, the next step is welding and joining the components. Various methods, including MIG welding, TIG welding, and spot welding, are utilized to create strong, durable joints. This stage is crucial for ensuring the integrity of the assembly, especially in automotive applications where safety is paramount.

Finishing Processes

The final stage involves finishing processes that enhance the appearance and durability of the sheet metal assemblies. This may include:

- Surface Treatment: Such as galvanizing or powder coating to prevent corrosion.

- Painting: For aesthetic purposes and additional protection.

- Quality Inspection: Ensuring that the finished products meet all specifications and standards.

Why Choose Devchhya Group of Industries?

Expertise in Sheet Metal Fabrication

At Devchhya, we have a team of skilled professionals who utilize advanced techniques and technologies in sheet metal fabrication. Our expertise ensures that we deliver precise and durable assemblies that meet international standards.

Comprehensive Range of Products

We offer an extensive array of sheet metal assemblies, including body panels, brackets, frames, and custom components. Our products are designed for a variety of applications in sectors such as automotive, aerospace, and industrial manufacturing.

Quality Assurance

Quality is our top priority. We adhere to stringent quality control processes to ensure that every sheet metal assembly meets the highest standards of durability and performance. Our commitment to excellence has earned us a reputation as a trusted supplier in the industry.

Customized Solutions

Understanding that each client has unique requirements, we provide customized sheet metal solutions tailored to specific needs. Our design team works closely with clients to develop products that align with their specifications and objectives.

Competitive Pricing

We believe in offering the best value for our clients. Our competitive pricing, combined with superior quality, makes us the preferred choice for businesses looking for reliable sheet metal assembly solutions.

Timely Delivery

With a streamlined production process and efficient logistics, we ensure timely delivery of all our products. Our commitment to punctuality helps our clients maintain their production schedules without delays.