Understanding Metal Pressed Parts:

Metal pressed parts are components created by shaping metal sheets through a series of processes, including stamping, bending, and forming. The metal is subjected to high pressure to achieve the desired shape and size. This process can be performed on various metals, including steel, aluminum, copper, and brass, making it a versatile manufacturing method.

The production of metal pressed parts involves several stages:- Design and Prototyping: Engineers create detailed designs and prototypes of the parts, ensuring they meet specifications and functional requirements.

- Material Selection: The appropriate metal is selected based on the part's intended application, considering factors like strength, weight, and corrosion resistance.

- Pressing Process: The selected metal sheet is fed into a press machine, where it is shaped into the desired form using dies.

- Finishing:: After pressing, the parts may undergo additional processes like deburring, coating, or plating to enhance their appearance and functionality.

Advantages of Metal Pressed Parts:

- Precision and Consistency: One of the main advantages of metal pressing is the ability to produce highly precise components with consistent dimensions. The use of advanced machinery and dies ensures that each part is manufactured to exact specifications, minimizing variations.

- Cost-Effectiveness: Metal pressing is a cost-effective manufacturing method, especially for high-volume production. The efficiency of the process reduces material waste and labor costs, allowing manufacturers to offer competitive pricing.

- Versatility: Metal pressed parts can be produced from a wide range of materials, making them suitable for various applications. This versatility allows manufacturers to cater to diverse industries, from automotive to electronics.

- Strength and Durability: Pressed metal components are known for their strength and durability. The pressing process enhances the metal's structural integrity, making it capable of withstanding harsh conditions and heavy loads.

- Customization: Manufacturers like Devchhaya Group of Industries offer customization options for metal pressed parts. Clients can request specific shapes, sizes, and finishes to suit their unique requirements.

Features of Metal Pressed Parts:

- High Tolerance Levels: Metal pressed parts are manufactured to tight tolerances, ensuring they fit perfectly into their respective assemblies.

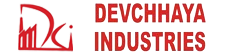

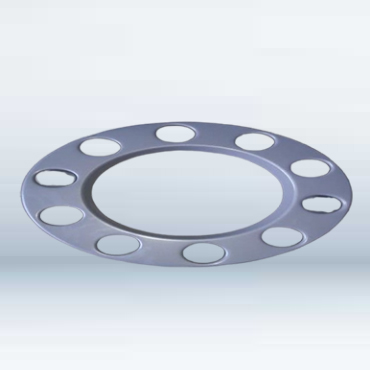

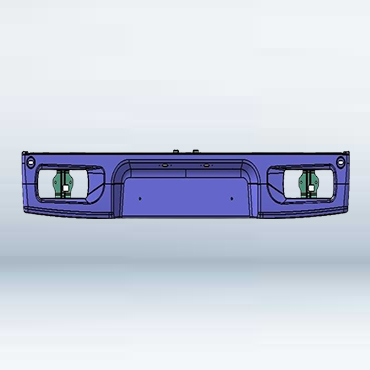

- Complex Shapes: The stamping process allows for the creation of complex shapes that would be difficult or impossible to achieve through other manufacturing methods.

- Surface Finishing Options: Metal pressed parts can be treated with various surface finishes, such as powder coating, anodizing, or plating, to enhance their appearance and protect against corrosion.

- Lightweight Design: Depending on the material used, metal pressed parts can be lightweight yet strong, making them ideal for applications where weight reduction is crucial.

Devchhaya Group of Industries stands out as a leading manufacturer, supplier, and exporter of metal pressed parts, offering a comprehensive range of solutions tailored to meet the diverse needs of various industries. With a strong focus on quality, precision, and customer satisfaction, the company is committed to delivering products that enhance efficiency and performance. The advantages, features, and benefits of metal pressed parts make them an integral component in modern manufacturing. Their versatility and reliability ensure that they will continue to play a crucial role in various sectors, from automotive to aerospace and beyond.